Jm-tronik > Maszyny cnc >

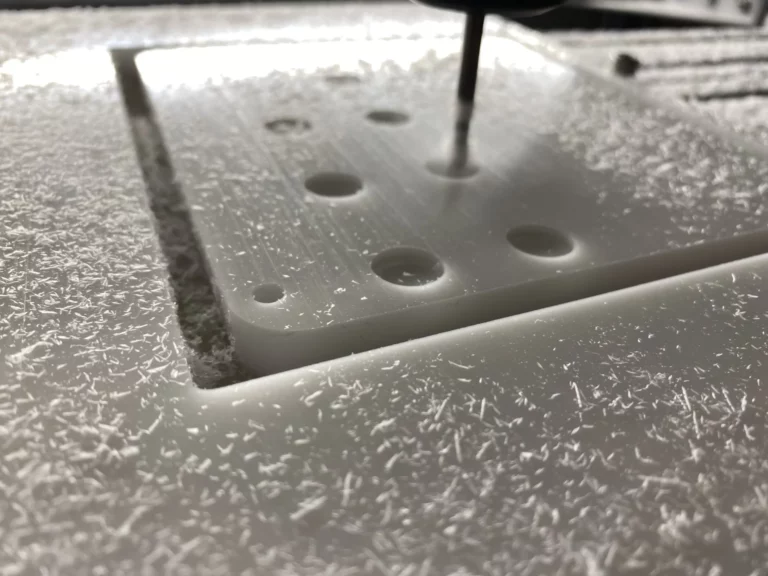

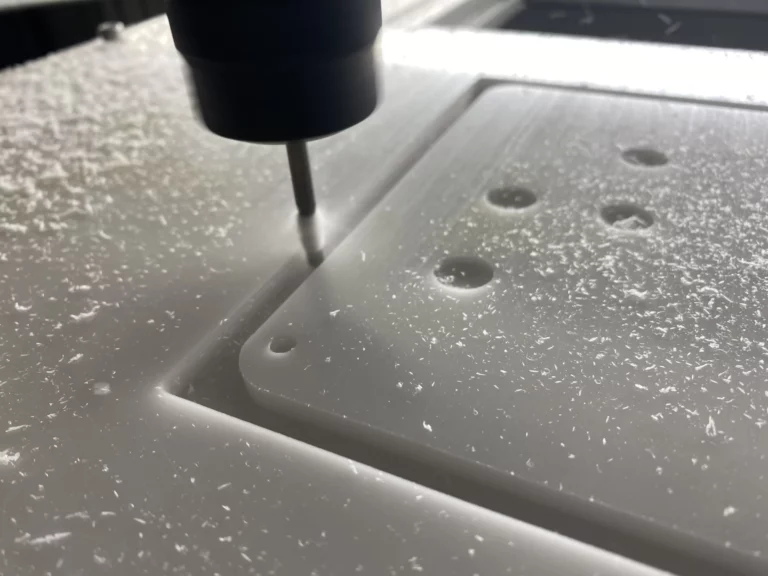

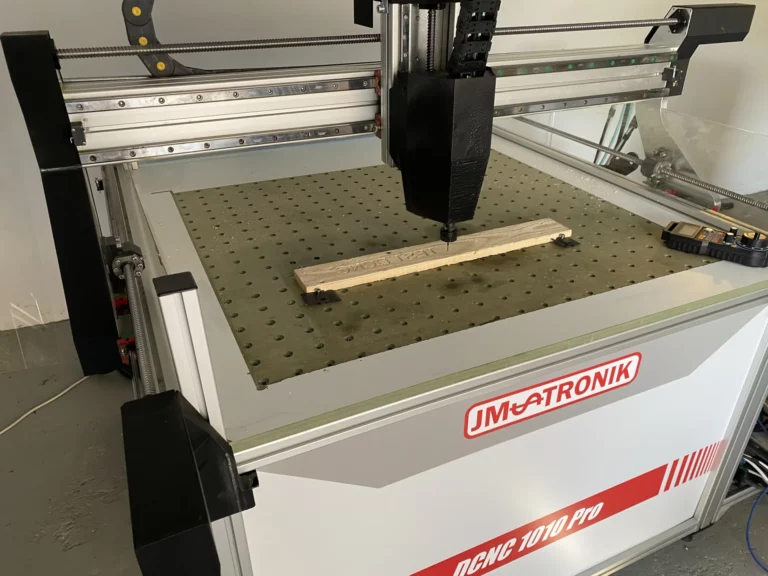

Cutter cnc qcnc to szybka, precyzyjna i uniwersalna maszyna wyposażona w frezy CNC, noże oscylacyjne, wrzeciona ATC, głowice znakujące i bigujące. Dedykowana jest dla branży reklamowej, obuwniczej, tekstylnej i wielu innych.

Ta przecinarka cnc oferuje duże obszary robocze, szeroką gamę narzędzi skrawających, dodatkowe akcesoria, takie jak wrzeciona ATC, moduł druku 3D czy moduły laserowe. Jej konstrukcja pozwala każdemu warsztatowi osiągnąć najwyższe prędkości skrawania bez utraty jakości.

Router is made out of high quality aluminum reinforced with concrete in crucial points which makes it very light and solid.

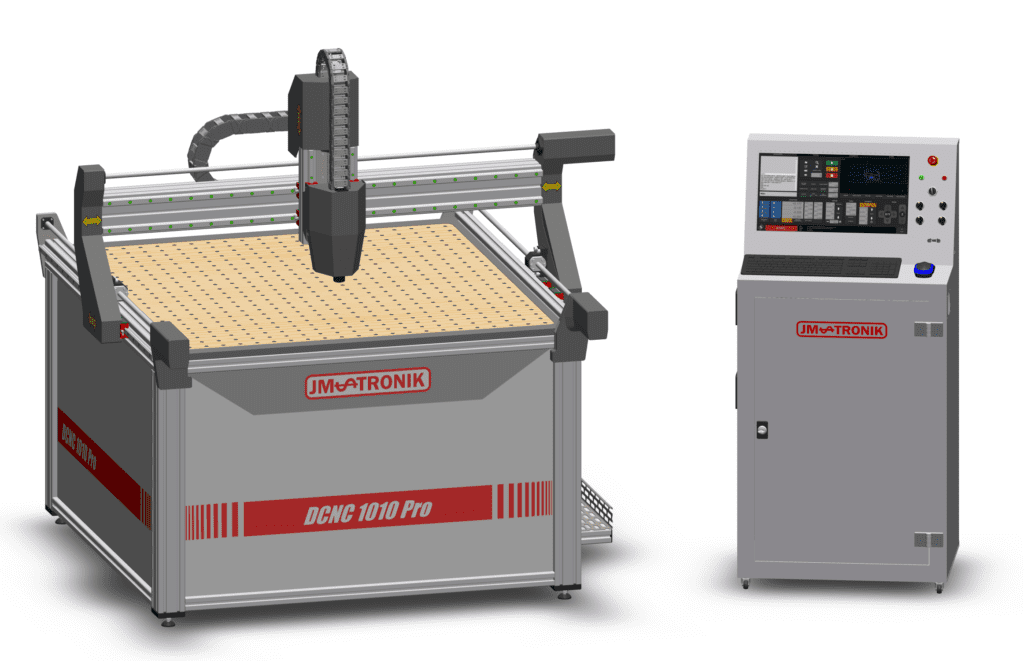

Table size:

Table type: T-slot aluminum / Vacuum Table / Hybrid Table

Gantry Clearance: 450 / 650 mm

Machine size:

Machine Weight: 199 – 899 kg

X-axis: 1000 | 1500 mm

Y-axis: 1000 | 1500 | 2000 | 2500 mm

Z-axis: 200 mm | 450 mm

2,2kW, water cooled, solid and high quality spindle. Quiet and long lasting bearing-based construction. Spindle RPM are ranging from 6 to 24k rpm. It is also equiped with bigger inverter to prevent it from rpm drops when under big load.

Optional: ATC 2,2 kW | 3,6 kW | ATC 3,6 kW | 6kW | ATC 6 kW

Programming resolution: 0.006mm

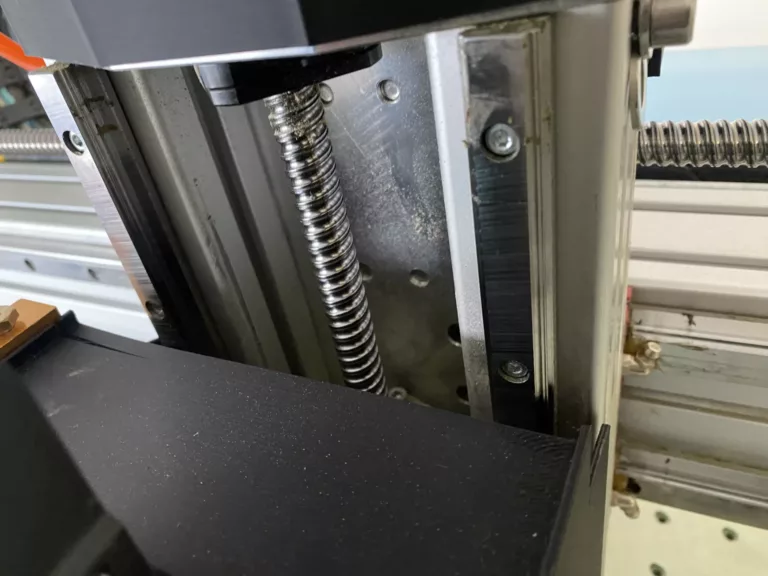

Ball Screw positioning accuracy: +-0.17 mm/m

Repeatability: +- 0.02mm

Certificate: cert.pdf

1-year basic warranty

2-year extra extended warranty

Program: Mach3

Dedicated 2,5D CAM program operated on windows 7 or above

The Defty Design of QCNC cutters from jm-tronik focuses on maximizing precision and speed while minimizing the weight of the machine. To achieve this goal, the design uses high-quality aluminum and fibro-concrete materials.

The combination of aluminum and fibro-concrete in the Defty Design of the QCNC cutter provides a lightweight stable platform for high-speed, precise cuts. The materials used in the design allow for increased speed, precision, and durability, ensuring that the QCNC cutter will perform at its best for years to come.

DCNC Routers are highly versatile machines capable of working with a variety of materials, including:

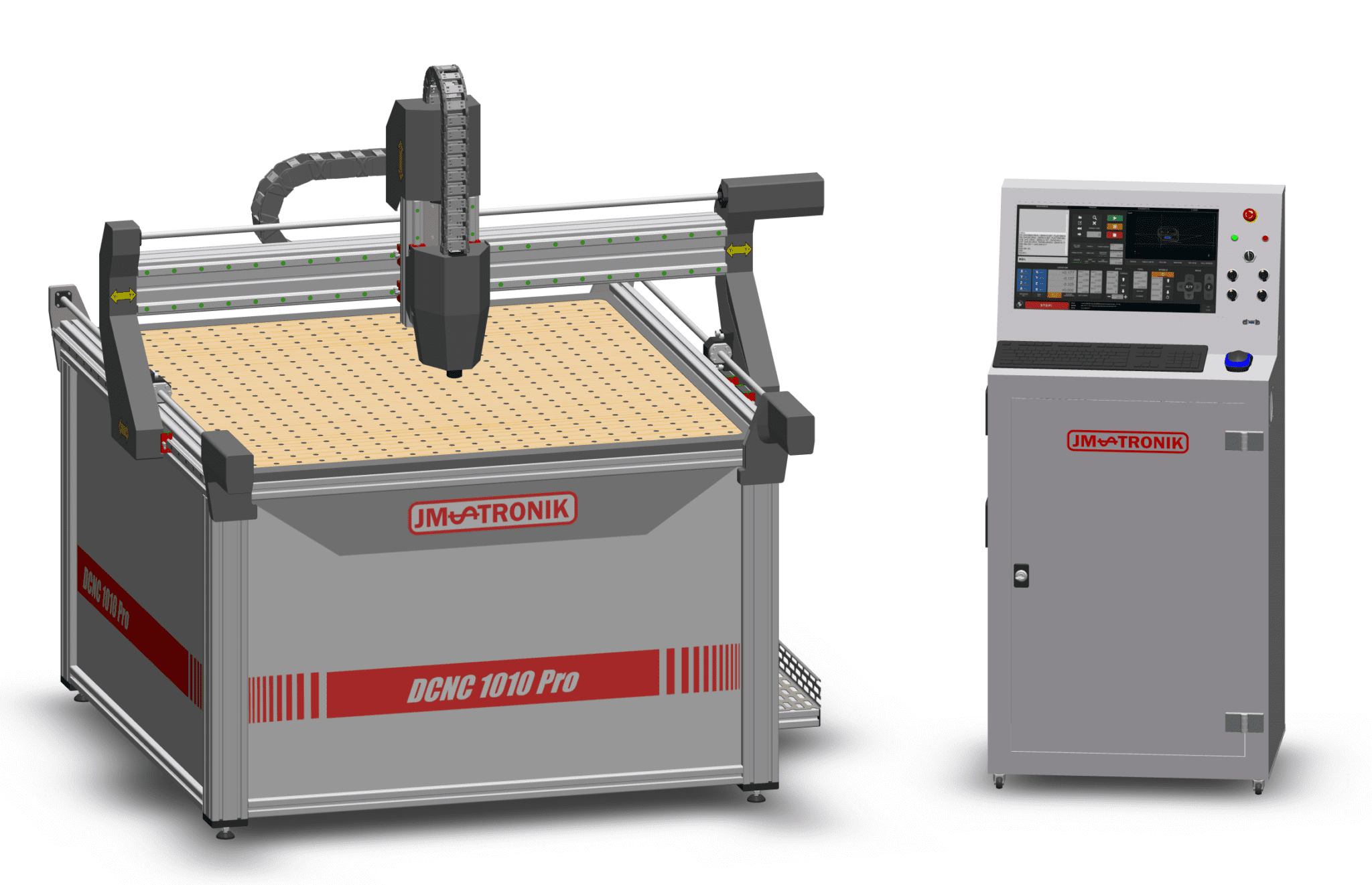

Milling with Automatic Tool Changer (ATC) is a high-efficiency solution for industrial and manufacturing operations. It is designed to work with precision and speed, reducing the time and effort required for milling operations.

The ATC system allows to automatically change between different tools, which is particularly useful when working on a variety of materials and projects. This feature increases the machine’s efficiency and productivity by eliminating the need for manual tool changes.

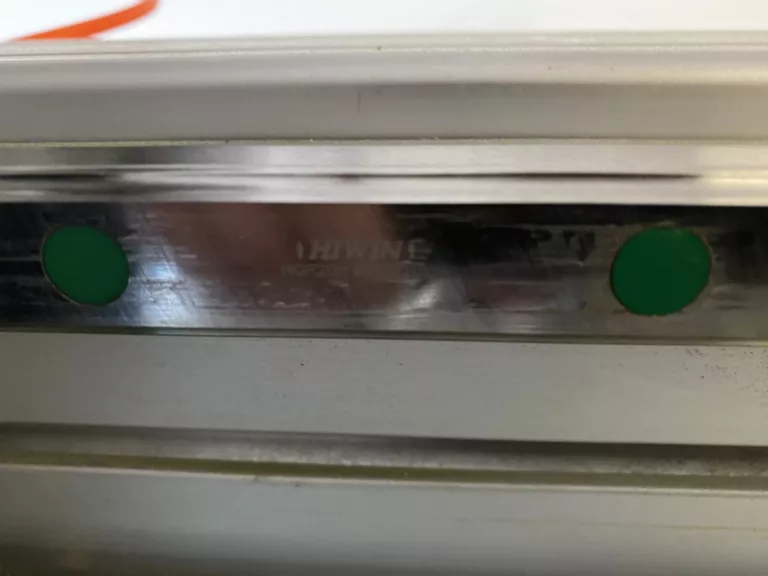

QCNC cutters from jm-tronik are known for their high-quality parts and components, which contribute to the efficiency, precision, and reliability of the machine. The following are some of the high-quality parts used in QCNC cutters:

The modularity of QCNC pertains to its ability to integrate multiple manufacturing functions into a singular, versatile machine. This modular design enables an extensive range of production capabilities, such as milling, 3D printing, laser cutting, and plasma cutting. The flexibility of the machine facilitates customization to suit specific manufacturing requirements, promoting cost-effectiveness and adaptability.

Moreover, the modular design allows for seamless maintenance and upgrades, ensuring optimal performance throughout its service life. DCNC’s modularity stands as a testament to its engineering prowess, delivering exceptional manufacturing efficiency and versatility.

QCNC

Informacje o produkcie i wsparcie:

(+48) 22 299 74 46

* The above offer is informative and does not constitute an offer within the meaning of art. 66 §1 of the Civil Code. For more information please contact jm-tronik.

Szybkie menu stron

Wszystkie maszyny

Robotyzacja spawania

Zapisz się!

Nie przegap nowych premier, informacji o targach a także porad spawania laserowego.

© 2024 JM-TRONIK Wszelkie prawa zastrzeżone.

Administratorem pozostawionych danych będzie JM-TRONIK Jan Matiakowski. Wprowadzone dane będą przetwarzane w celach marketingowych, w szczególności w ramach marketingu bezpośredniego oferowanych przez nas produktów i usług. Podstawą prawną przetwarzania jest uzasadniony interes Administratora. Udostępniając swoje dane, zyskujesz prawo do ich modyfikacji, usunięcia, dostępu do danych, a także wyrażenia sprzeciwu wobec marketingu realizowanego przez Administratora. Twoje dane mogą zostać przekazane podmiotom współpracującym z nami w zakresie marketingu bezpośredniego, zgodnie z obowiązującymi przepisami prawa.