Security

● Sensitivity improved tenfold with collision detection using torque sensors.

● More than 21 TÜV safety functions, meets functional safety standards: ISO 13849-1, ISO 10218-1/PL d, category 3; ISO 15066.

● Redundant monitoring of sensor information in a dual channel and independently certified safety controller.

● Position holding accuracy better than ±0.1 mm with power on and off, powered by suction brake and dynamic feedforward compensation.

Performance

● State-of-the-art motion control technologies for industrial robots: OptiMotion, TrueMotion and SyncMotion.

● Excellent robot path accuracy supported by dynamic feedforward compensation and dynamic modeling based on more than 2,000 parameters.

● Increased lifting capacity by 20% thanks to a customized motor drive control system.

Multitasking

● Powerful yet flexible robot control based on a hybrid force and position control system.

● Performance of force control tasks improved by more than three times with highly dynamic force control.

● Precision grinding and assembly without the need for expansion, thanks to built-in sensors at the joints and a complete set of force control processes.

Ease of use

● Direct learning control with 1N based on point position and continuous trajectory.

● Graphical programming interface with block diagrams allows users to get started within an hour.

● Friendly development environment and support for an open ecosystem with more than 100 extension tools in 5 categories.

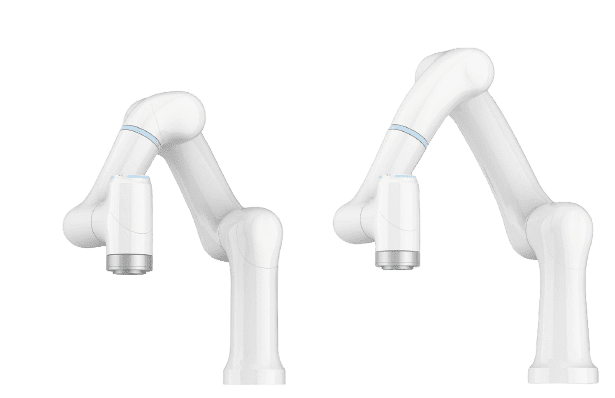

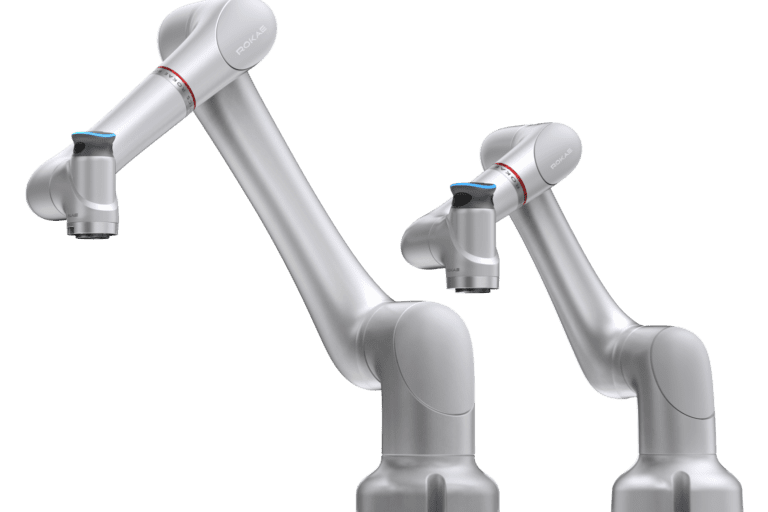

● Proprietary offline programming software Rokae Studio, which supports simulations for all models.

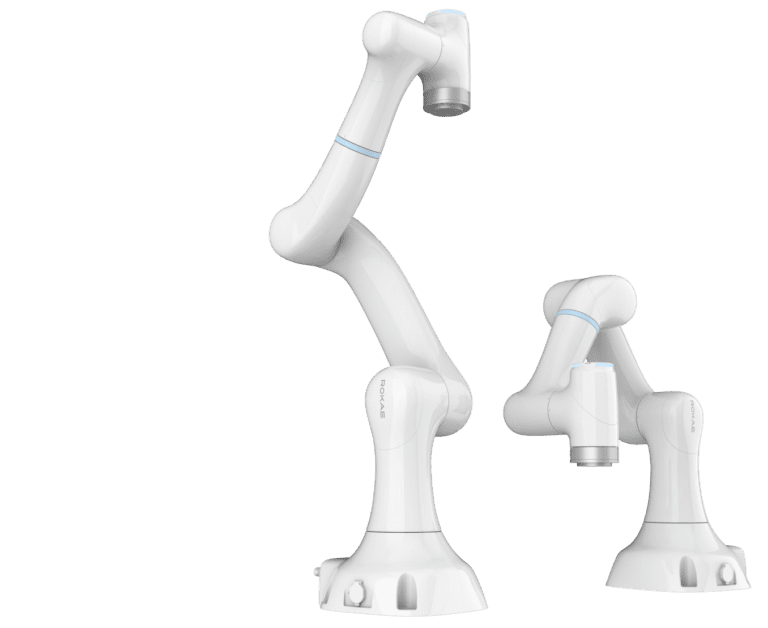

● The possibility of using a design without a control cabinet, which reduces the weight of the system by 50% and enables quick installation and flexible deployment.

Reliability

● Motion planning based on dynamic constraints ensures high performance, overload protection and extended life.

● More than 100 verification experiments, 20+ factory tests and MTBF > 80,000 h.

● IP67 protection level meets the requirements of harsh industrial applications.